What Is a Photovoltaic Diesel Hybrid System?

In many regions of the world, power grids are either inadequate or nonexistent. As a result, industrial consumers often ensure their power supply through diesel gensets. Five hundred gigawatts of power from diesel gensets provide industrial companies with electricity worldwide. However, fuel costs for the gensets continue to rise. The price for one liter of diesel has already exceeded one U.S. dollar.

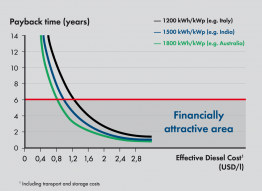

In addition, if the fuel has to be transported to remote regions, the effective costs increase even more as a result of the necessary storage. At the same time, PV system costs have dropped by more than 50 percent within the last three years; therefore, solar power is often the most economical alternative energy source for remote regions in the world’s Sun Belt. It simply makes sense to combine PV and diesel systems so that solar irradiation – which is both abundant and free – can profitably be used as an energy source in industrial applications.

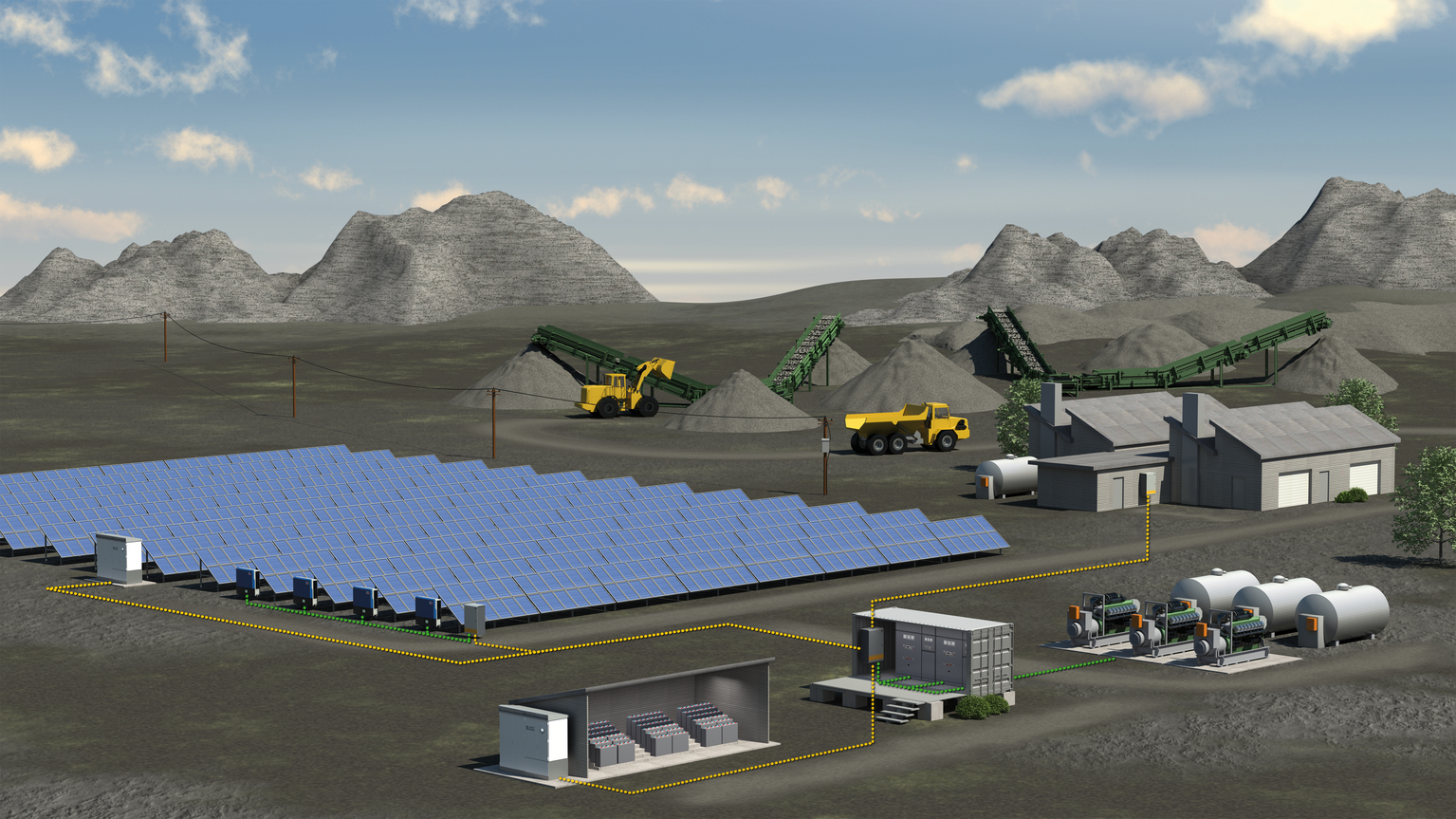

Last November, the first off-grid photovoltaic diesel hybrid system in the megawatt range went into operation in Thabazimbi, South Africa. Using the SMA Fuel Save Solution, the system complements the existing diesel energy supply with solar energy. The operator can save up to 450,000 liters of diesel per year and significantly reduce CO2 emissions. But how does that work? And what exactly is a photovoltaic diesel hybrid system?

What is a photovoltaic diesel hybrid system?

A “hybrid” is something that is formed by combining two kinds of components that produce the same or similar results. A photovoltaic diesel hybrid system ordinarily consists of a PV system, diesel gensets and intelligent management to ensure that the amount of solar energy fed into the system exactly matches the demand at that time. In contrast to conventional off-grid systems of up to 300 kW, in which a Sunny Island inverter serves as a master, the diesel genset itself performs this function.

How does a photovoltaic diesel hybrid system work?

Basically, the PV system complements the diesel gensets. It can supply additional energy when loads are high or relieve the genset to minimize its fuel consumption. In the future, excess energy could optionally be stored in batteries, making it possible for the hybrid system to use more solar power even at night. Intelligent management of various system components ensures optimal fuel economy and minimizes CO2 emissions.

What are the advantages of a photovoltaic diesel hybrid system?

In contrast to power supply systems using diesel gensets, and despite their higher initial cost, PV systems can be amortized in as little as four to five years, depending on the site and system size, and they have low operating costs.

In addition, PV systems are flexible and can be expanded on a modular basis as the energy demand grows. Compared to pure genset systems, a photovoltaic diesel hybrid system provides numerous advantages:

- Lower fuel costs

- Reduced risk of fuel price increases and supply shortages, thanks to optimized planning

- Minimal CO2 emissions (protects the environment and facilitates CO2 certificate trading)

SMA’s solution for photovoltaic diesel hybrid system technology is the SMA Fuel Save Solution. The information provided below explains how it works and other interesting facts.

What are the components of this photovoltaic diesel hybrid system?

1. PV inverters

SMA inverters are the central components of the SMA Fuel Save Solution. Designed specifically to be used in weak utility grids, they are suitable for high voltage and frequency fluctuations. They also remain extremely productive in harsh ambient conditions, such as heat, moisture and salty air, among others. Both the Sunny Tripower and the Sunny Central can be used in a photovoltaic diesel hybrid system.

A centralized PV system contains only one string into a central point, such as the SMA Sunny Central, where direct current is converted to alternating current. In a decentralized PV system, the PV power is divided into many strings, which are converted into alternating current by several inverters, such as the SMA Sunny Tripower. Both the SMA Sunny Tripower and the SMA Sunny Central work with the SMA Fuel Save Controller to perform grid management functions.

The choice between a centralized or decentralized system depends on many factors. Both system installation costs and operating costs must be considered. For example, maintenance work on a decentralized system is not complicated, even in inaccessible areas. If service is needed, local electricians can replace individual inverters. However, remote monitoring is simpler for a centralized system structure.

2. PV Array

The solar power is generated in the PV modules, which can be mounted on the ground or on a roof, depending on local conditions. SMA inverters are compatible with all PV module types and technologies currently available on the market.

3. SMA Fuel Save Controller

The SMA Fuel Save Controller provides the perfect interface between the gensets, PV systems and loads, managing demand-based PV feed-in into the diesel-powered grid. As the central component of the SMA Fuel Save Solution, it ensures maximum security with reduced fuel costs and minimizes CO2 emissions. The SMA Fuel Save Solution can achieve 60 percent of PV capacity compared to installed genset capacity. This means 600 kW of PV power can be generated from one megawatt of the installed genset power. The Fuel Save Controller consists of three modules:

- PV Main Controller Module – Controls PV power injected into the Diesel grid. Provides optimal PV feed-in capacity by evaluating current genset and overall load status.

- Interface Module – Records and transmits data and set-points as the interface between the PV Main Controller and inverters.

- Data Acquisition Module – Quickly and precisely analyzes the current load and grid conditions in the system and transmits the data to the PV Main Controller Module

4. Diesel genset

In grid-remote regions, pure diesel systems often provide the energy for industrial applications. They constitute the local grid, ensuring a constant power supply to all connected users. Because the gensets require a constant fuel supply, they are often the system’s highest operating cost. In regions with weak utility grids, diesel gensets often serve as a backup during grid power outages.

5. Genset system house

This includes the monitoring and control systems for the diesel gensets. The genset system house is the central terminal and point of common coupling

6. Optional storage batteries

To boost the efficiency of the entire energy supply system, it is advisable to include a storage battery. When solar irradiation is insufficient or energy is needed after dark, the storage battery supplies the required energy, ensuring optimal hybrid system operation. SMA is working on a battery inverter specifically designed for such industrial applications.

7. Industrial loads

Application-specific load profiles, such as heavy-duty industrial loads for mining or processing raw materials as well as for agricultural use, are generally characterized by loads with high starting currents and widely fluctuating load curves. Intelligent system management ensures that generation and load are perfectly matched. It achieves constant system stability by reacting quickly to generation and load performance spikes, such as when a conveyor belt is turned on.

When and where does a photovoltaic diesel hybrid system make sense?

For industrial, large-scale loads in remote regions, complementing diesel gensets with photovoltaics is the ideal solution under the following conditions:

- When the effective cost of diesel exceeds one US dollar per liter.

- When intelligent communication between the genset and PV systems facilitates demand-oriented use of PV power.

- When local solar irradiation conditions allow the use of PV. It’s especially economically viable with PV yields above 1,500 kWh/kWp.

Conclusion

Photovoltaic diesel hybrid systems can be amortized especially quickly in sunny regions, with little or no grid access. SMA system technology maximizes the use of solar energy in combination with diesel aggregates. For industries such as mining, raw material processing, agriculture (such as flower farms and water desalinization systems), and tourism (facilities with a high energy demand), low power generation costs, quick operational readiness, maximum reliability and availability are fundamental. The environmental benefits are also convincing: CO2 emissions and noise pollution are significantly reduced, minimizing the environmental impact. Environmentally friendly and cost-effective? Yes, we can do that.

Dear SMA Team ,

Could you please propose the best devices that can fit below requirements . the client has no grid and they are Genset 100 %. NO battery system required

1. Main Office- 220 kw working hours : 10Hrs day time

2. Store & workshop area- 185 KwWorking hours 10Hrs in day time

Solar Power Generator to provide Minimum 30% of required Power of total Required power in each area.

Hello,

I am Photovoltaic Student and currently designing the system. I want to design 500 W (0.5 kW) system with grid tie system which can also works in the absense of the Grid.

I will be happy to get any assistance.

I will be waiting for kind response.

Regards

Saeed Ahmed

We are diesel supply company base in Abuja – Nigeria as of recently we have diversify into altanative energy and want provide this hybrid solutions to our numerous clients starting from goverment offices, schools and hospitals including industries who rely on diesel generators for power supply . How can you be of assistance towards meeting our goals and do you have any distributors representing my regions . Thanks .

we are based at Cochin .we are looking for dealership of your products

i need about this topic in accordance : mathematical component,electrical component,mechanical component,computer science

Hi ,

I am impressed with inverters performance at the sites i have seen, Do you have fuel saver /Load management products available for smaller scale such as 50kW/or 100kWp also.

Thanks

Sumit

Hi;

Can you please let me know what are the required information from the site in order to design a system like that.

As an example, do we need to know the load? available area? an so on.

Regards;

Samir