Solar Straight Talk: SMA Expert OpEd – The Real Costs of Module-Level Power Electronics (MLPEs)

Humans are creatures of habit. Life is busy, and once we start something we generally roll with it… until strong enough evidence (or pain) is presented otherwise.

I’ve worked in solar for 8 years as a system designer and territory manager, and here are my arguments why MLPE’s just don’t make sense.

System Reliability

For a period spanning from the mid 2010’s through the early 2020’s the general philosophy of residential solar sales was that microinverters were advantageous because “if one microinverter goes out you only lose one panel,” as juxtaposed to a single inverter responsible for the entire system, where if that inverter went out the entire system would be down. This tracks well if you don’t spend too much time thinking about it. The reality, and what plays out in the field, bears fruit on the side of a quality-made string inverter.

A single underexplained truth lies at the bottom here. What is the failure rate of solar panels? An article from EnegySage titled “How often do solar panels fail” (updated February 29th, 2024) states:

“According to a 2017 study from the National Renewable Energy Laboratory (NREL), 0.05% of solar panels installed since 2000 will need replacement due to failure from age, exposure to the elements, or manufacturing defects.”

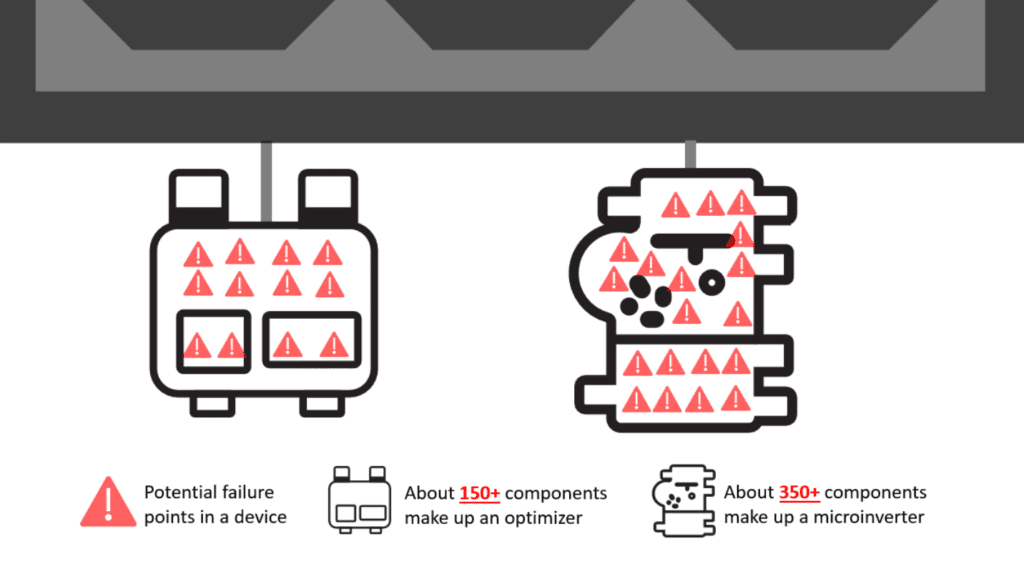

0.05%! That… is an incredibly small amount. The actuality is – if a MLPE is giving an error code it is far more likely that the MLPE has failed. It rarely has anything to do with the solar panel itself! The MLPE’s are monitoring themselves, not the production of the panels.

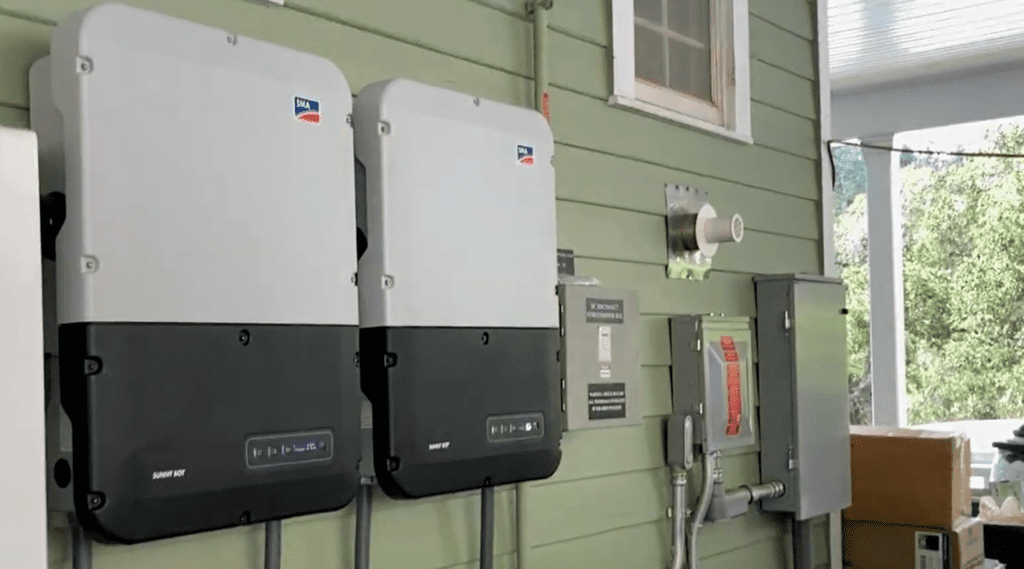

From the standpoint of reliability electronics do not like extreme heat, cold, water exposure, or general fluctuations in climate, and yet that is exactly what MLPE’s are exposed to on the roof, day in and day out for years. The solution of our SMA Sunny Boy Smart Energy (SBSE) is to let panels do their work on the roof, bring the DC current off the roof, and do the conversion to a usable AC current in the garage or on the side of the home in an accessible location with a more controlled climate. The inverter is the heart of the system, the component ultimately responsible for the financial payback to the end user. At SMA we believe our architecture allows for the best long-term satisfaction for homeowners while giving installation companies an easier and less expensive fix for the next topic: maintenance and Repowering.

Ease of Maintenance and Repowering

If an inverter registers a failure, the homeowner (in general) isn’t going to have any idea what is wrong. They are going to call their installation company, and that company is going to have to truck-roll to the site to diagnose the issue. If the system uses MLPE’s, it will involve climbing on the roof and locating the device registering an error. From there the installer will have to figure out the path forward. Depending on the timespan since installation, many of the MLPE models will no longer be available causing compatibility issues in tandem with a more physically challenging fix.

With the SMA SBSE a service technician can simply walk up to the inverter to perform any required work. An additional free service offered for the SBSE is SMA Smart Connected, a platform that can initiate a remote -return merchandise authorization (RMA) by utilizing the System Manager built into the SBSE inverter. In many instances, this will negate the need for an installer to roll a truck for diagnostics, saving time and money. The replacement inverter will land at the specified address listed in the Smart Connected service.

With repowering, there are no issues with single device incompatibilities, and the SBSE can be used to repower almost any string inverter system. The SBSE was also designed with a wide voltage window, allowing for recapture of some kWh production in older arrays. This is going to be a huge boon for installers as there are many older systems in the 15–25-year range that will need new inverters to carry their systems forward. Which bring us to our next topic: Environmental Care.

Environmental Care

The solar industry is helping drive new technologies that will increasingly reduce our global consumption of fossil fuels. That said, we are still an industry, and industry makes things, and those things have a lifespan. What happens to them when that lifespan is over? Options for recycling solar equipment are being developed, but let’s operate here from a fundamental notion: less is more.

For the same reason we believe that less electronics and failure points equal higher yield and reliability, we believe that less components equals a better environmental outcome. Less to recycle, less possible trash, easier breakdown when the product has reached the end of its usable lifespan. Which brings us to our last and possibly most relevant topic: CapEx Cost Savings plus LCOE.

CapEx Cost Savings Plus LCOE

Along with offering less failure points and having less opportunity for e-waste, not utilizing MLPE’s also achieves something even more tangible – less money spent. If the average microinverter (MI) costs $150 and the project requires (25) 400-watt solar panels for a 10kW system, that totals $3,750 for the inverters. That cost discrepancy only grows as panels are added, and this is just on the PV only side of things.

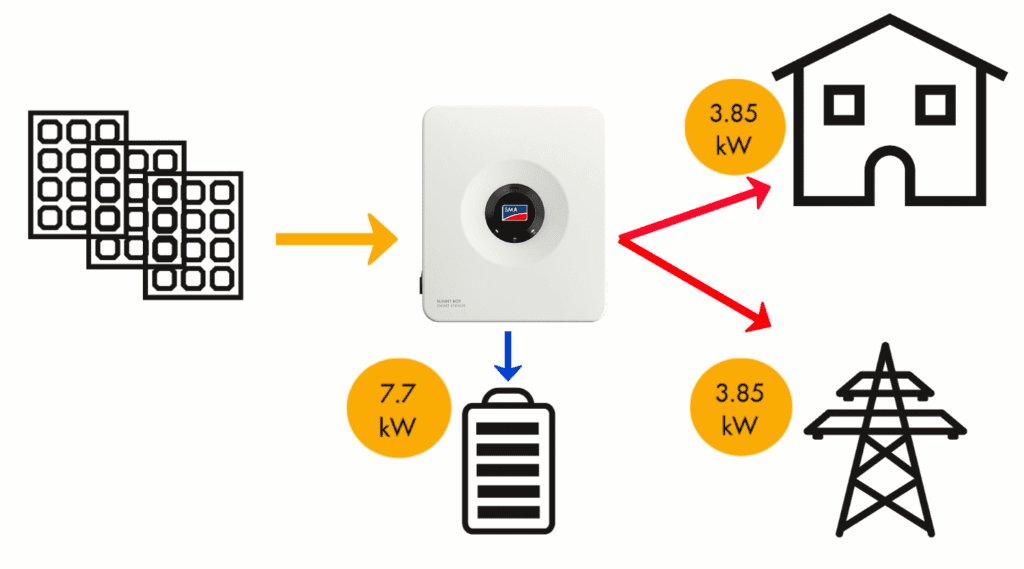

With the future of residential solar bound to include higher adoption of storage, the SMA SBSE also boasts a 200% DC to AC ratio. Where once a high DC to AC ratio didn’t make much sense from an ROI standpoint, now homeowners can add panels to maximize production, fast charge their battery with excess current, while saving upfront cost by utilizing a smaller inverter.

Over time, the architecture of the SBSE will yield the best LCOE for homeowners and installers alike. For installers, there are cost savings in their service budget as Smart Connected can alleviate truck rolls for diagnostics and the fix happens at the location of the single inverter; not on the roof. For homeowners the SBSE also provides a LCOE advantage in the form of a seldom discussed issue – losses due to heat.

MLPE’s such as MI’s and DC optimizers are constantly running, which generates heat. All solar panels and inverters have temperature coefficients, basically stating that as temperatures rise, output reduces. By locating a single inverter off the roof, the SBSE allows the PV modules to reach their full potential for energy production, then takes the DC current off the roof and does the DC to AC conversion in the air-cooled inverter. Over time this is a double whammy of positive features – less CapEx investment AND less production losses over time.

In conclusion, while module-level power electronics (MLPEs) like microinverters have been marketed as a solution to improve reliability and efficiency in solar systems, they often introduce more complexity, potential points of failure, and system losses. These effects are all magnified under harsh environmental conditions. The SMA Sunny Boy Smart Energy (SBSE) provides a more robust alternative by centralizing the critical DC to AC conversion in a controlled environment, away from the elements. This approach not only enhances system reliability, but also minimizes environmental impact by reducing the number of electronic components that can fail and require recycling. Finally, the SBSE system offers significant cost savings both in initial capital expenditure and long-term operational costs, providing a better overall Levelized Cost of Energy (LCOE) for homeowners and installers. By focusing on fewer, more reliable components, the SBSE architecture ensures higher performance and greater satisfaction for all stakeholders involved.

Feel free to contribute!