SMA Aerial Thermography, Keeping Your PV Plant Profitability Soaring

A properly maintained solar system can accelerate investment payback and increase yields by up to 30 percent. Whether it is a commercial, utility or storage project, hot spots can be indicative of future system issues, so SMA insists on finding those potential problems before they can affect system profitability.

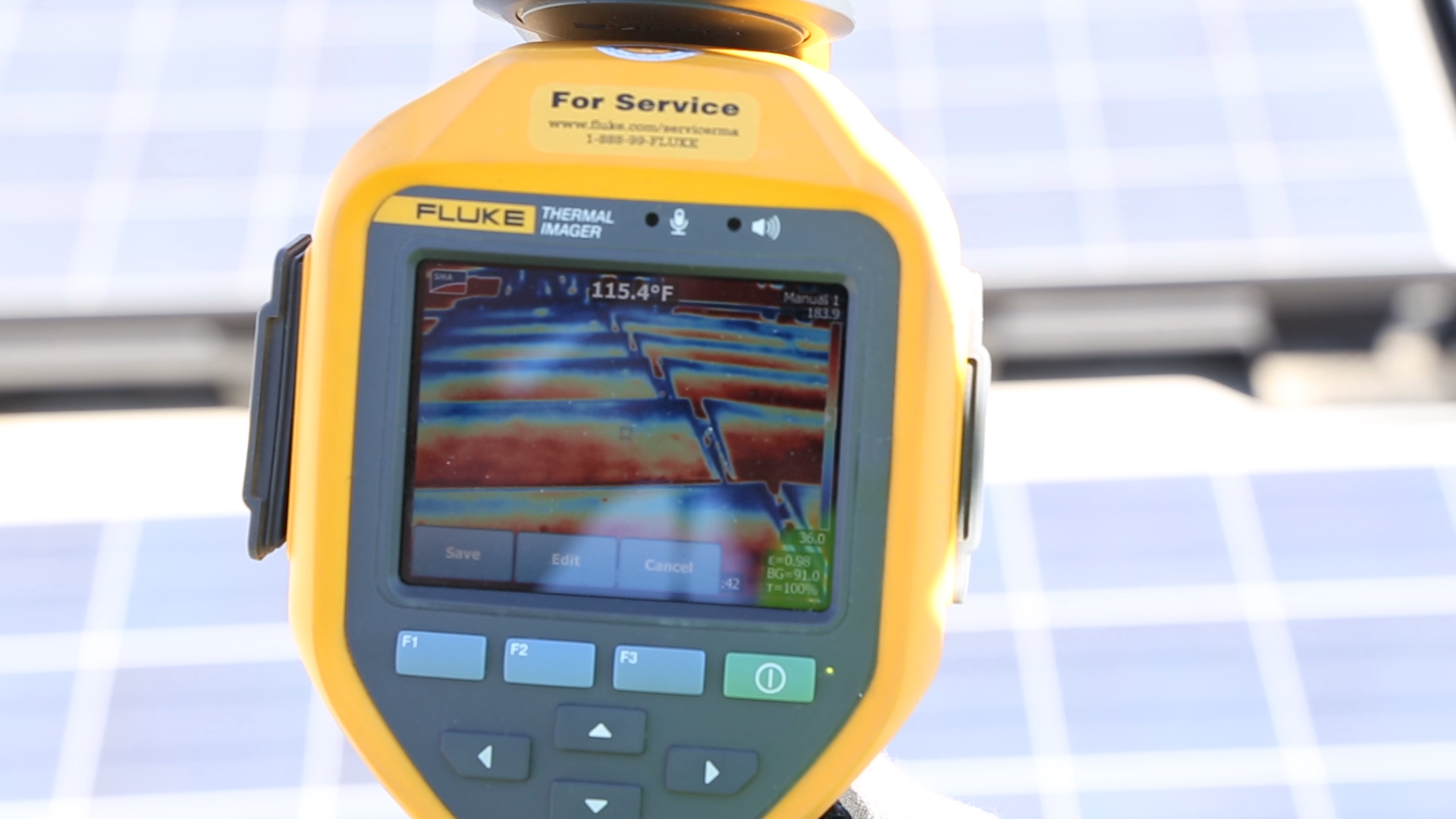

Proactive monitoring activities, including regular thermography of all plant components, are key in detecting temperature and equipment degradation issues in advance of any revenue loss. These temperature differentials can occur throughout the array due to cell or diode failures, fuse failures, wiring failures, partial shading, and module degradation.

However, how do you effectively monitor PV plants that are simply too large and too time consuming to examine thoroughly from the ground? With SMA Aerial Thermography!

SMA, always at the forefront of new solar technology, now delivers an extremely accurate method of data collection, dramatically reducing OPEX considerations and maximizing power production. SMA Aerial Thermography is so precise it can detect issues down to the cell level, significantly decreasing the time spent identifying and diagnosing problems.

This sophisticated method of airborne infrared inspection, performed by a team of experts certified by the FAA and the American Society of Non-Destructive Testing, brings an entirely new level of system visibility and asset security.

Advanced mapping technology along with the ability to archive and compare with future data further elevate SMA’s capability to deliver the most comprehensive inspection services in the PV industry.

Hi Alexandra

I am a drone operator located in the Nothheast do you have a referral or partner program?

Thanks

Joe

Caption Hights llc

My company is Starpower-RE from the Philippines. I am interested to buy the SMA THERMOGRAPHY. Please send me information and price.