Tech Talk: The Importance of Proper Equipment Clearances

Equipment clearances are as much a part of the solar industry as the modules themselves. Inverter manufacturers have recommended clearances for proper airflow around the unit to prevent premature derating, the decreasing of power to protect power electronics. Typically solar installers use the recommendations set-forth by the inverter manufacturer when determining location and spacing of the inverters. However, in some cases the inverter clearance needed is not always black and white.

Sunny Boy Clearance

Most Sunny Boy US models recommend a 12-inch clearance on each side of the inverter. This clearance allows the heat from one inverter to be dissipated and not affect neighboring units. In a single inverter installation, proximity to walls, switch gear and other obstacles should be considered. Heat dissipation is also highly dependent upon where the inverter is located, both geographically and physically. During a site inspection, the installer may decide that the inverters can be placed closer together if the heat can still be properly dissipated.

Real-Life Examples

It may be acceptable to challenge the recommended clearances set by the manufacturer under certain circumstances. Perhaps inverters are mounted in an air-conditioned location, since there is cooler air circulating around the inverters less clearance is needed. Conversely, if an inverter is mounted on a southwest exterior wall in Phoenix, Ariz., best practices dictate that the 12-inch clearance should be followed.

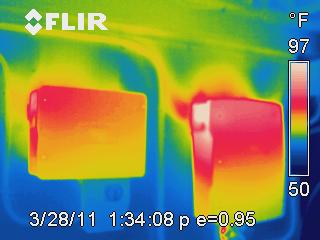

In the installation displayed as example one, there is not even 12 centimeters in-between the inverters, much less 12 inches. These Sunny Boy inverters, installed in New Mexico, would surely have derated if left in this configuration. Ultimately, they were separated onto an opposite wall to ensure proper heat dissipation.

Proper ventilation is a key component to keeping the inverter cool. Periodic spot checks should be conducted to ensure optimal performance. The inverter displayed as example two was installed on the southeast side of a house and the fan was running at full speed when checked in the early morning. Even though the inverter was not derating, the inverter’s blocked exhaust screen was causing the inverter to work harder than necessary. After cleaning the debris from the fan intake and exhaust screen, the fan turned off within an hour.

Power Loss vs. NEC Compliance

Inspectors are trained to check inverter clearances to ensure a properly installed PV system that is safe to operate for the next 20-plus years. A specific section of the National Electrical Code (NEC) positions installation compliance as set forth by the inverter manufacturer. However, the strict nature of NEC 690 is often contrasted by an interpretation of “the spirit” of the inverter clearance compliance articles. Adding to this challenge are inverter installation manuals that can be confusing, causing the inspector to rely on his or her own judgment.

SMA addresses inverter clearance confusion in a document entitled, “Manufacturer’s Declaration: Minimum Clearances to Neighboring Devices/Inverters.” It explains that clearances closer than the SMA recommendation becomes a concern due to the potential of lost power production, not an NEC safety compliance issue. This document can be used during inspections to help eliminate some of the questions surrounding proper PV inverter clearance compliance.

Would mounting the inverters 2-3 inches apart result in the voiding of warranty?

Please can I have the quotation of sunny Boy 11,000 TL -US ,Sun Modules 250W On -Grid , Off Grid Modules 250W ,and Battery SuPac 2.0 ,SuPac Lion Battery

Hello sir, I just read the article above, I was just curious if the manufacturer specs have changed? In the manual, the clearance shows 8″, but the article above calls for 12″, your feedback is appreciated.