The Practical Box Behind the Scenes: SMA String-Monitor and String-Combiner

The only time anyone really mentions PV array junction boxes is when listing the individual technical components of a PV power plant. One reason they might be completely overlooked is because, compared with inverters, medium-voltage components and modules, they are quite inconspicuous. But without them, nothing works. Anyone who overlooks these seemingly unimportant boxes will lose out and shouldn’t be surprised if they see decreased PV power plant yield and increased maintenance outlay.

In its April 2015 edition, the magazine “Sonne Wind und Wärme” even devoted four pages to PV array junction boxes under the title “The Neglected Component”. Author Martin Frey, writing in Sonne Wind & Wärme (April 2015 edition):

“PV array junction boxes fulfill a range of functions: They bring the strings together, contain protective devices and protect the cable ends against climatic influences. They can also be used for monitoring. To ensure that everything functions reliably, top quality is essential. But despite these numerous key functions, very often too little attention is paid to PV array junction boxes during project planning, with the focus instead lying on the brands and technical specifications of PV modules, inverters and so on. And yet, PV array junction boxes can play a key role in the success or failure of a PV project. ( … ) inferior PV array junction boxes can cause a PV system to temporarily fail or lead to low system efficiency, resulting in not only loss of revenue but also increased maintenance. In the worst case, a fire could break out in the PV array junction box—with all the associated consequences.”

The article also happens to be just in time for the market launch of two brand-new devices from SMA. I talked to product manager Sandro Meyer about the features and functions of the new SMA String-Combiner and String-Monitor.

Interview: “Intelligence Makes the Difference”

At Intersolar 2015 in Munich in June, SMA will be showcasing a new String-Combiner and String-Monitor. What capabilities do these new SMA devices offer?

Sandro: Both the String-Combiner and String-Monitor bring together the individual strings from the PV modules and protect electrical components. The boxes are made from glass-fiber-reinforced plastic because of its durability and stability. The SMA devices offer excellent electrical insulation, UV protection, self-extinguishing properties and excellent acid resistance. The String-Combiners and String-Monitors offer excellent corrosion resistance even in “aggressive” environments, making them ideal for outdoor use under all ambient conditions.

We now know what these devices have in common. How do they differ from each other?

Sandro: While the String-Combiner simply combines—that is, gathers—the individual strings from the PV modules in the PV field, the String-Monitor can collect data and send it directly to the interface in the inverter, where it is processed further in a matter of seconds. Measured values can be made available via Modbus to other systems such as SCADA and/or sent to Sunny Portal. The parameters that are measured include the string currents, the voltage in the connected area of the PV generator, the inner temperature in the String-Monitor and the status of the surge arresters and the disconnector. External module or ambient temperature sensors and pyranometers can also be connected. In this way, key data is collected and, if any discrepancies arise, PV system yield losses are averted just in time.

Quality is key when it comes to PV array junction boxes. How do you ensure that the quality of the String-Combiner and String-Monitor meets even the most stringent requirements?

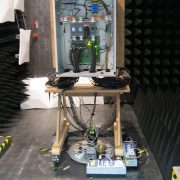

Sandro: Our devices undergo numerous tests, including climatic tests, whereby device behavior under hot, cold and high-humidity conditions is tested; rainwater and sprinkler tests; EMC (electromagnetic compatibility) tests; fuse heat tests under operating conditions (for obtaining data on aging processes); overload tests; field tests in PV systems; and service-friendliness tests.

The device remains completely intact even after being dropped from a height of one meter!

Special Feature: Exterior Fuses

Sandro, as product manager, you know the new devices inside out. Are there any other features you’d especially like to mention?

Sandro: Yes, two things. First, the low weight of the String-Combiner and String-Monitor. Compared with the predecessor device, the Sunny String Monitor (SSM), the String-Monitor weighs much less—at just 34 kilograms, it is a real lightweight even compared with products from other manufacturers. This really helps to reduce installation time. The device is also much cheaper than its predecessor. And, second, I’d particularly like to mention the external fuses, which hang out of the bottom of the SMA String-Monitor and make it really easy for the individual strings to be connected without the use of tools. The connectors, which were specially developed by Phoenix Contact and are TÜV-certified, also permit a high degree of flexibility during system design. In the words of Phoenix Contact: “A special feature of the SMA String-Combiner boxes is the fact that the string fuses are located outside the switch cabinet. This eliminates the primary source of heat inside the housing, thereby preventing thermal influences and premature aging of the components.”

One final question. Intersolar kicks off on June 10, 2015. Will visitors be able to see these new SMA devices for themselves?

Sandro: Of course. You can see the String-Monitor at our stand (SMA stand B2.210) and the String-Combiner at Leoni Studer’s stand. The SMA colleagues at the stand will be happy to answer any questions you may have.

Thank you for your time.

The following links contain all the detailed technical specifications you need to know on the SMA String-Combiner and String-Monitor.