Service Tip: Give It Space

Inverter manufacturers recommend maintaining a certain amount of clearance around the units to ensure adequate air circulation. This helps prevent derating, which is when performance is reduced to protect the electronic components. It is important for installers to know and follow the recommended clearances whenever possible so as to avoid additional expenditures for ventilation systems.

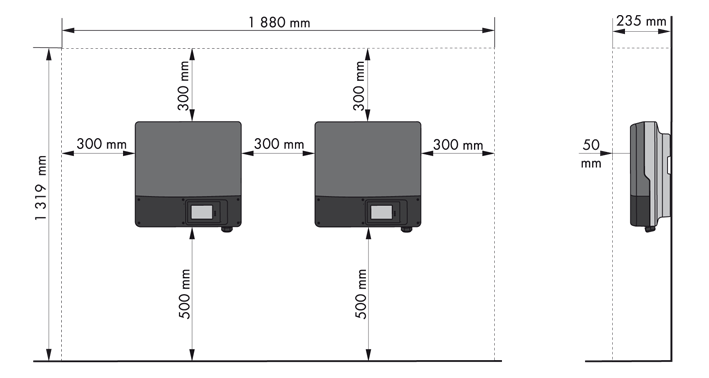

Clearance for SMA inverters

The recommended lateral clearance for SMA inverters is between 3.94 inches and 11.81 inches (100 mm and 300 mm), depending on the model and the individual product groups’ different cooling concepts.

The devices’ installation guidelines always include detailed information on the subject.

It is necessary to maintain appropriate clearance, so that there is sufficient heat flow without negatively affecting adjacent equipment and other external devices, such as ventilation systems. When installing individual inverters, wall clearance, switch units and other obstacles must be taken into account.

Heat dissipation depends greatly on the installation location ‒ from a physical and geographical standpoint. During a site inspection, the installer can decide whether and where the inverters can be installed with less than the recommended clearance, so long as proper heat dissipation can still be ensured.

Example 1: These inverters (U.S. version) will have a reduced output over time because they are installed too close together.

Real world examples

It is possible to deviate from the manufacturer’s recommended clearance distances under certain conditions. For example, the inverters won’t require as much clearance if they are installed in a climate-controlled location because the ventilation will make the air cooler. Conversely, inverters that are installed in subtropical climates absolutely have to maintain the recommended clearances.

In Example 1, the clearance between the inverters is a few centimeters at most. These inverters would likely have reduced output in this configuration, depending on the season. To address this problem, some of the devices were later moved to the opposite wall to ensure appropriate heat dissipation.

The inverter’s ventilation helps keep the device at the right temperature, which is why the fans should be checked regularly. The inverter pictured in Example 2 was installed on the southeast side of a house. When inspected in the early morning, the fan was already running at full throttle. Although its output hadn’t fallen yet, the inverter had to work harder than actually necessary because of the clogged air exhaust grille. The fan intake and air exhaust grille were cleaned, and the fan shut off again after an hour.

For more information on minimum clearance to neighboring objects / inverters, see our manufacturer’s declaration.

Feel free to contribute!