Fire safety of PV systems

Worldwide several million households enjoy safe, clean and cost-efficient energy from PV systems. Despite this, some online media sources claim that PV systems cause fires and put firefighters at great risk. These articles spread fears about PV safety and are sometimes used to sell add-on safety products like module shutdown devices. Fortunately, these fears are unfounded.

In this post, we show evidence from comprehensive studies that indicates existing PV systems are generally safe, fires are rare, and firefighters are still able to work safely.

1. Fires caused by PV systems are rare

Independent testing and research institutes TÜV Rheinland [1] and Fraunhofer ISE [2], have found that less than 0.006% of PV systems have caused fires in Germany. Other countries like Japan, Netherlands and Australia report similar figures [3] [4]

2. Fires were mainly caused by human/external factors

Of the small number of PV system fires, “human errors” are mainly to blame. TÜV’s report surveyed 210 PV fires and found that poor workmanship and poor design account for the majority of fires caused by PV systems (38%) [1].- Installation mistake: DC connections not mated properly, badly crimped connectors, no strain relief etc.

- Product failures: PV modules or inverters.

- External influence: animals, lightning etc.

- Planning failure: poor mechanical and electrical design (e.g. incorrect selection of DC isolators, cabling).

Poor design or dodgy installation can lead to fire as there is increased risk of electrical arcs. Arcs commonly occur where there is an unintentional break in the electric circuit.

In Germany, Australia and the UK, the majority of faults have occurred in the DC side of the circuit (PV modules, DC wiring, DC isolators, etc) [1] [3] [4] [5]. The probability here is high because there are many components and connections on the DC side. That means there are more chances for something to go wrong: for e.g. one of the components is faulty or one of the connections is not properly made.

3. Are module-level shutdown devices needed?

In short, no. Here´s why:

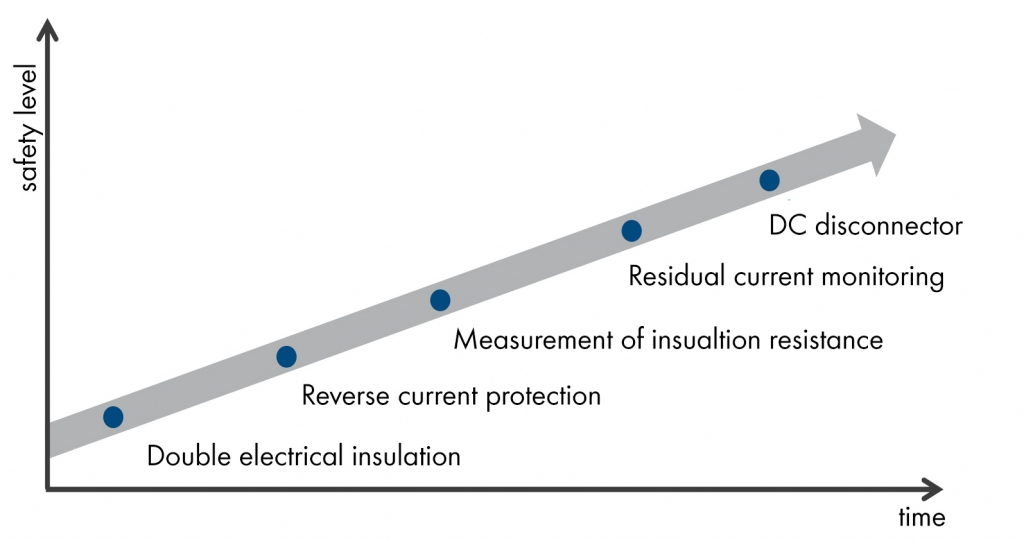

PV system safety has improved over time with the introduction of new safety devices. You may think that adding additional safety devices would reduce the chances of a problem. However, adding more devices increases the number of connections and components that could fail. In the case of adding module-level shutdown devices, the number of DC connections roughly doubles! This increases the number of sites for a potential problem, whether it is component failure or an installation mistake like not properly making connections.

Module-level shutdown devices are also unnecessary for firefighters to safely attend an incident involving a PV system. The independent testing institute TÜV does not propose the mandatory inclusion of module-level shutdown devices: “reasoning has led fire departments to shift away from the general demand for a shutdown on the grounds that theoretically any switch-off device can fail” [1].

If module level power electronics are needed in special cases, plant operators should take care to use as little devices as possible. In some systems, such as those that have persistent shading during the day, the TS4-R-Optimiser can be used to maximize yield from the PV system and minimize stress on the shaded module. The TS4-R system can be selectively deployed only to affected shaded-modules to minimise the number of components and connections.

4. Additional safety devices are redundant

Firefighters are well trained in dealing with fires in houses with PV systems and know about the appropriate precautionary measures. These precautions include keeping a minimum distance between the nozzle and PV array such that there is no risk of electrocution to the firefighter [1].

Conclusion

Fires are extremely unlikely in PV systems when they are properly designed and installed. Analysing previous fires at PV systems has confirmed this. PV systems can be made even safer by addressing the most frequent root causes of DC arcs, which are mostly related to human errors during the design and installation stage. There is no need for module-level-shutdown devices as firefighters may already manage risks onsite and they do not address the common root causes for PV system fires.

Find more details on the topic in the whitepaper.

Bibliography

| [1] | Sepanski et al, “Assessing Fire Risks in Photovoltaic Systems and Developing Safety Concepts for Risk Minimization,” TÜV Rheinland Energie und Umwelt GmbH, 2018. |

| [2] | Laukamp et al, “PV Fire Hazard – Analysis and Assessment of Fire Incidents,” 28th EU PVSEC 2013, Paris, 2013. |

| [3] | A. Chiaramonte, A. Smith and Z. Hood, “Fire Safety of Solar Photovoltaic Systems in Australia,” Worcestor Polytechnic Institute, 2016. |

| [4] | D. Bende, “Brandincidenten met fotovoltaïsche (PV) systemen in Nederland,” TNO, 2019. |

| [5] | BRE National Solar Centre, “Fire and Solar PV Systems – Investigations and Evidence,” 2017. [Online]. Available: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/630639/fire-solar-pv-systems-investigations-evidence.pdf. |

![A breakdown of the reasons for PV system fires in Germany. Data source: TÜV [1]. A breakdown of the reasons for PV system fires in Germany. Data source: TÜV [1].](https://www.sma-sunny.com/wp-content/uploads/2019/04/root-cause-262x189.jpg)

Feel free to contribute!