Bundled System Solution for Decentralized Large-scale PV Power Plants

Many photovoltaic professionals know that the larger the PV plant, the faster small reductions in power negatively affect yields – at least, as long as they remain undiscovered. The new SMA Cluster Controller provides just the right solution for PV plants with string inverters.The scalable system solution offers flexible management of decentralized large-scale PV power plants, even up into the multi-megawatt range.

Cable-based Bundling

I spoke with Dr. Andreas Paetzold, Senior Product Manager of Medium Power Solutions, about the advantages the SMA Cluster Controller offers:“The SMA Cluster Controller offers reliable monitoring and simultaneous control of up to 75 string inverters thanks to the Ethernet-based Speedwire fieldbus and the high-performance dual-core processor,” said Andreas Paetzold. “The high-performance bus system with 100 Mbit/s also ensures optimum data transfer rates for reliable plant monitoring and processing of arising measured values, status updates, and plant control commands.”

If you take a closer look, using Speedwire as a continuous high-speed bus system not only offers corresponding plant monitoring, but it also offers reliable controlling using digital or analog measurement signals or by Modbus® data protocol*¹. In addition, a wide range of connection options for sensors and additional signals from the system offer an even more precise assessment of performance or profitability.

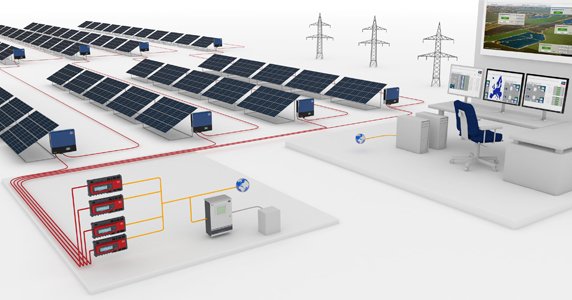

System overview: Decentralized large-scale PV power plant with SMA Speedwire fieldbus, SMA Cluster Controllers, SMA Power Plant Controller

Clustering – Decentralized and Modular

The SMA Cluster Controller’s modular system design allows the power plant output to be scaled as required. “The customer only needs to use one SMA Cluster Controller for power generation plants up to maximum 1.5 megawatts. However, if larger PV power plants are planned, they can be easily equipped with additional PV clusters according to the modular design principle,” explained the product manager. Standard Ethernet components can be used for the entire network cabling. This is a key factor when it comes to saving costs and ensuring return on investment.

Information, Backup and Restoration

Another remarkable feature is the SMA Cluster Controller’s ability to quickly notify the operator or service personnel about yield-relevant events.Three options are possible: direct email dispatch, a signal contact and/or via the Sunny Portal*². Yield-relevant events may include, for example, device faults or also remote-controlled active power limitations carried out by the grid operator (feed-in management measures according to the Renewable Energy Sources Act (EEG)).

An additional interesting function is the “backup restoration” option. This allows you to archive all the settings of an SMA Cluster Controller and import them to a “new” device. That is useful, for example, if a company always uses identical settings for the SMA Cluster Controllers in its systems. If an SMA Cluster Controller must be replaced, a replacement device can quickly be restored with all the settings using an archived backup file.

*¹ Modbus is a registered trademark of Schneider Electric and is licensed by the Modbus Organization, Inc.

*² The Sunny Portal offers another solution for comprehensive plant management, which provides even more functions for plant and yield monitoring such as processing measured values, performance analysis, presentation, reporting and mobile data access.

Links for More Information

Product page SMA Cluster Controller

Data sheet SMA Cluster Controller

User Manual SMA Cluster Controller

Hello Gerrit

We have a plant of 1 Mw which was commissioned last year in December by Sunbelt which is a sister company of SMA. The system comprises of FSC with 34 Sunnytripower 25000 and a cluster controller.

We had issue with the inverter not starting in during the morning periods and had to reset the certain inverters every morning. At times we had to reboot the FSC to get the inverters producing. We did contact SMA service in Particular MR. Dirk who found difficulties of why the inverters could not start producing without being reset every morning.

He then suggested we have the inverter connect to Cluster controller as to make analysing of any issues easier. The problem is that the cluster controller installed can handle a maximum of 25 inverters.

We need your advice on if we install another Cluster controller of 25 devices or install a another one which can take upto 75 devices.

Your kind feedback would be highly appreciated

Regards

Jayesh

Dear Jayesh,

thanks a lot for your feedback. I will get in contact with you via email to quickly solve your issue.

Sunny regards,

Christian

Thanks for your Prompt response

Await your feedback

Jayesh

You mentioned in your blog about #LargeScalePVPowerPlants is very nice to gain more knowledge about Solar Power Plant installation. The useful life of any well maintained Solar Power plant is considered to be 25 years. Solar Power plants will be used beyond 25 years while power generation will be less. Many Solar Panel manufacturers guarantees the output of 90% up to 10 years and 80% up to 25 years. If you have any queries about SolarPowerPlantDesigning, Please visit our website.

We are using Power Plant controller in Solar plant , I would like to know upto what % of Grid voltage a Power Plant controller can support and ensure the plant is stable. We are seeing the plant tripping beyond 10% of Grid nominal voltage with power plant controller.

Will be much appreciated if we can get the details of the band width of the voltage level upto which PPC can support.

Hi Raju,

unfortunately it is not so easy to give you more information. The SMA Power Plant Controller (PPC) does not cause a shutdown. If the configuration of the PPC is not correct the PPC does not communicate with the inverters. But the PPC does not shut down the inverter. That’s why my colleagues suppose that your inverters are the problem. So please contact the Service Line from your inverter company.

Thanks and regards,

Annika

Hello Gerrit

I really found this blog very imformative and the cluster controller looks like a promising product from SMA.

I understand the benefits of using Ethernet communication in the field but face challenges in understanding the issues regarding the field cabling. The existing RS 485 interface is very popular in the industry owing to its ease of installation and reduced costs. How do you see Speedwire(Ethernet) being differnet?

Secondly, what about the grounding issues with Ethernet wiring?

And finally, what cost impact do you see upon migration to Speedwire from RS 485.

regards

solarguy

Hello solarguy,

first of all thank you very much for your compliment.

Here are a few key points for a better understanding:

Pro Speedwire:

– Normative and legal requirements (valid directives and standards) can no longer comply with RS485 (e.g. implementation time of control and regulation commands).

– Ethernet zeichnet sich in der Solar-Industrie als Zukunftsstandard ab. More and more manufacturers use this standard.

– Integration into existing local customer networks respectively the integration of pv plant is far more easier (e.g. SMA Webconnect).

Cost impact:

– Plug-and-play option saves a substantial amount of time and money and reduces efforts significantly. The usage of standard IT components such as cable, switch etc. simplifies the installation process as well (e.g. complicated remove of insulation of the cable core is no longer required).

– The daisy chain wiring through to two Ethernet ports (switched) makes the installation far more easier.

Here you can find even more information: http://files.sma.de/dl/17333/NEXTINNO-KEN122211.pdf

I trust the above resolves your queries. Should you have any further questions, please do not hesitate to comment again.

Best regards,

Gerrit